Lower Emissions, Greater Efficiency and Improved Occupational Safety in Cutting and Welding Processes

2025-09-09

Shanghai, China – September 9, 2025 - Under the motto “Precise cutting, perfect welding – complete solutions that connect and inspire,” industrial gases specialist Messer and Messer Cutting Systems will be presenting innovations at the welding and cutting trade show “Schweissen & Schneiden 2025” (Hall 8, Stand B17 and B23).

Using hydrogen as a fuel gas for oxyfuel technology reduces CO₂ emissions to zero during use and significantly reduces the emission of nitrous oxides and dust particles. At the same time, hydrogen makes it possible to achieve higher efficiency, better results as well as greater occupational safety and health. Industrial gases specialist Messer and Messer Cutting Systems have joined forces to drive forward the necessary developments, including both gases and special torches and nozzles.

Lowering emissions and improving quality are also the focus in the field of welding. Here, Messer is presenting solutions for hand-held laser beam welding along with an innovative shielding gas for welding unalloyed steels.

Cutting with hydrogen: HyCut offers a clear competitive edge

Two years ago, together with Messer Cutting Systems, Messer was the first industrial gases supplier to commercialize hydrogen for oxyfuel technology. Marketed under the brand name HyCut, the solution uses 100% hydrogen as fuel gas. Hydrogen contains no carbon atoms, thereby enabling oxyfuel cutting without emitting any CO₂. This helps HyCut users meet their own sustainability goals and comply with legal requirements.

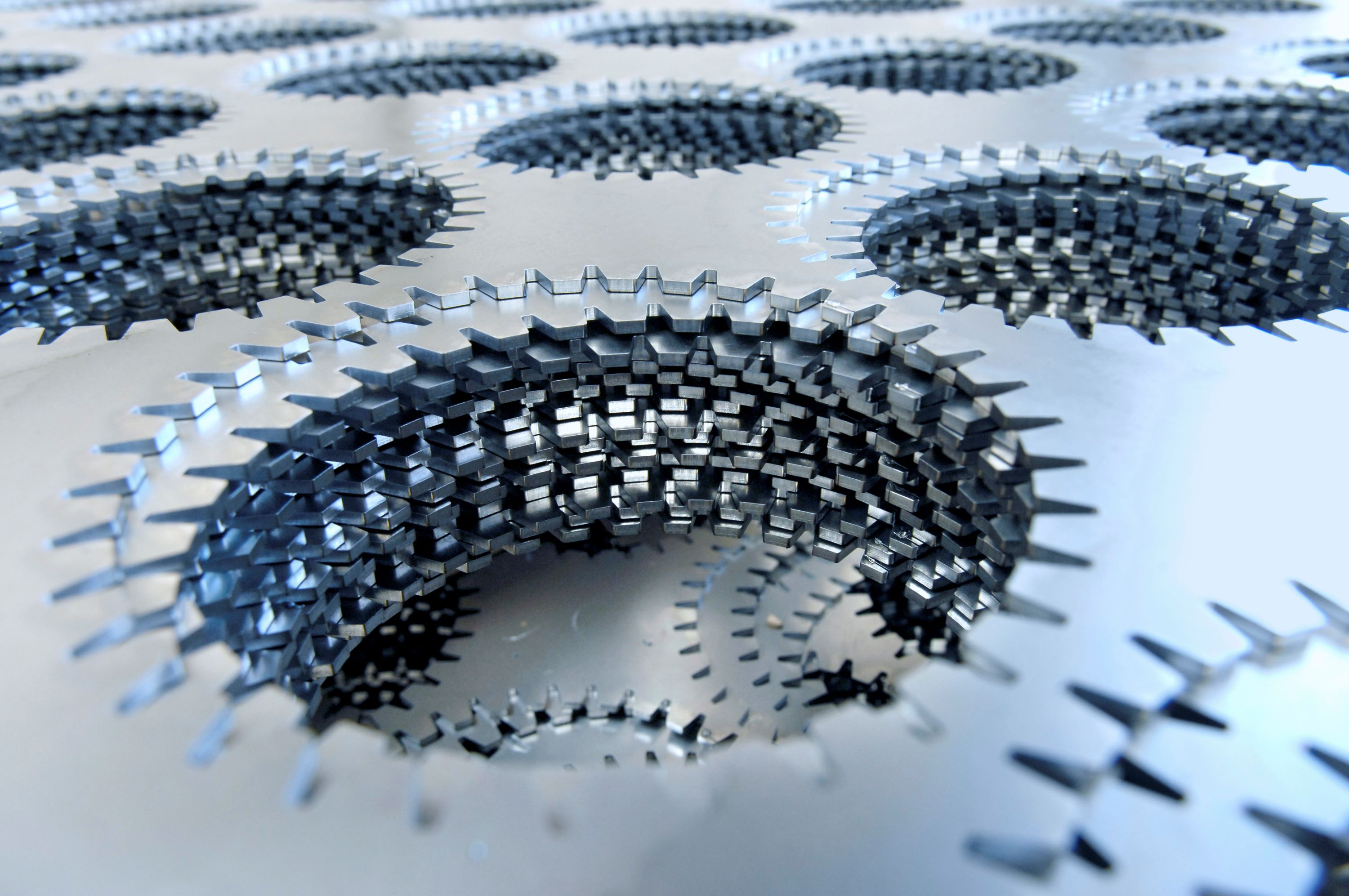

HyCut makes it possible to apply heat with absolute precision with performance that matches or exceeds that of acetylene. Moreover, the service life of the nozzles is extended and they are also easier to recycle because they require no chrome plating. Last but not least, the noise level drops by 5 to 8 dB(A). In addition to flame cutting, HyCut has also proven itself in heating and straightening, brazing and flame spraying applications. Live demonstrations at the trade show will present HyCut’s advantages.

Laser cutting: New benefits with nitrogen and oxygen

The sharp increase in laser power in recent years has opened new opportunities: When cutting unalloyed steels, we can use the exothermal reaction process with oxygen to dispense with the energy share. This results in cut surfaces with less oxidation and significantly higher feed rates. For a long time already, nitrogen has been one of the alternatives used to produce components that require little reworking. Up until now, the disadvantages have included heavy burr formation on the underside of the components. This has changed thanks to new mixtures of nitrogen with a two to five percent share of oxygen. At the trade show, Messer will be showing customized solutions that optimize the use of nitrogen and oxygen according to need.

Hand-held laser beam welding: Innovative welding gases

Hand-held laser beam welding is fundamentally changing the world of welding. It features high precision, low heat input, high welding speed, easy handling and minimal component distortion. Messer has developed a new portfolio of shielding gas mixtures for these applications and will be presenting at the trade show how these gases, marketed under the brand Lasline, can be optimally used for hand-held laser beam welding.

Welding unalloyed steels: Less welding fumes and particles

At the cutting and welding trade show “Schweissen & Schneiden 2025”, Messer will present the shielding gas Ferroline C6 X1 for unalloyed steels. This special mixture of argon, carbon dioxide and oxygen, significantly reduces the emission of welding fumes and particles. This enables users to comply, simply and effectively, with increasingly demanding health protection regulations around the world. The advantages of this gas mixtures will be showcased at the trade show in practical demonstrations.

About Messer China

Founded in 1898, Messer is the world’s largest privately held specialist for industrial, medical, electronic, and specialty gases, serving customers across Asia, Europe, and the Americas. Since entering the Chinese market in 1995, Messer has built a strong local presence with more than 40 entities nationwide. Backed by an extensive production and supply network, over 2,500 highly dedicated employees and deep industry expertise. Messer delivers reliable, customized gas solutions that help drive innovation and enhance operational efficiency. Today, Messer is a trust partner to many of China’s leading companies across a wide range of industries.