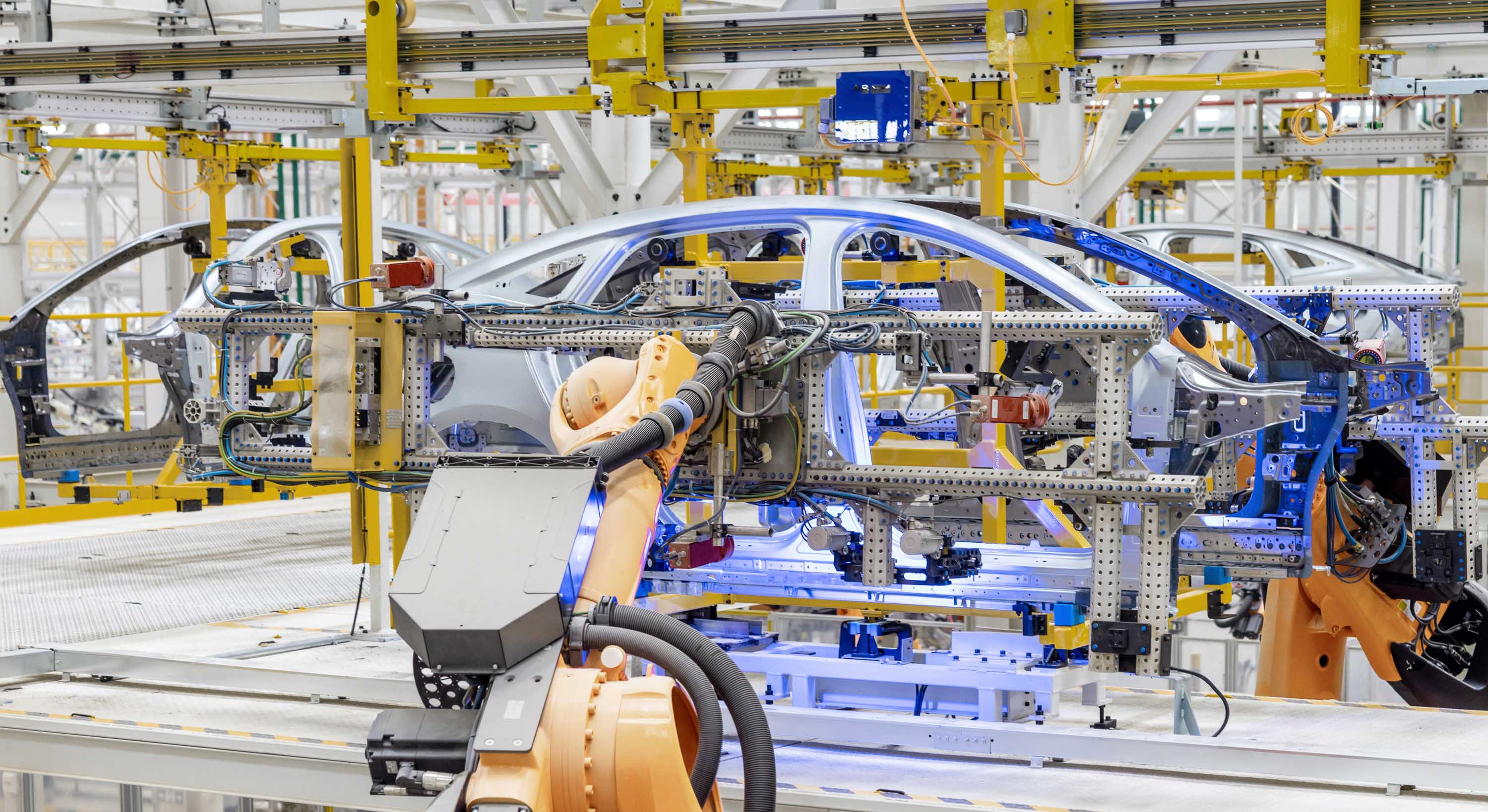

Automotive Body Welding

Messer’s Ferroline X4 shielding gases keep automotive welding smooth, while helping make vehicles lighter, stronger and more energy efficient.

Whether for traditional fuel vehicles or new energy cars, manufacturers today face the challenge of lightweight construction. This requires the use of lighter and thinner materials, particularly high-strength hot-formed steels with tensile strength up to 2 GPa, such as DP steels, TRIP steels, and martensitic steels. Welding these advanced materials presents considerable challenges for existing processes. Because ultra-high-strength hot-formed steels are typically zinc-coated, the evaporation and damage of the zinc layer during welding can weaken the corrosion resistance of the body. Ensuring reliable joints has therefore become a critical factor in automotive body manufacturing.

In recent years, many automakers have increasingly adopted advanced joining methods—such as laser-arc hybrid welding and laser spot welding—alongside traditional resistance spot welding. Regardless of the method, shielding gases are always essential. Messer’s Ferroline X4 shielding gas, when used together with CuSi3 welding wire, provides dependable protection for welding high-strength hot-formed steels and offers distinct advantages:

• Excellent weld pool fluidity, minimizing defects such as lack of fusion and edge undercut.

• Low oxidation, producing bright welds while reducing post-weld cleaning.

• Improved filler metal capability for smoother weld seams.

• Higher achievable welding speeds.

Gases Available from Messer

Ferroline X4:

①Cylinder

②On-site Mixing with Bulk Liquid

Exhaust System Welding

Messer’s Inoxline X2 shielding gases provide reliable protection for welding automotive Exhaust System.

The automotive exhaust system is made up of components ranging from high-temperature manifolds to low-temperature tailpipes. Exhaust manifolds and front pipes are typically manufactured from austenitic stainless steels, as these parts operate at 700–900 °C. For such applications, the materials must deliver resistance to high-temperature oxidation and corrosion, as well as sufficient strength under high-heat conditions. Mufflers and rear pipes, on the other hand, operate at lower temperatures, generally in the 600–100 °C range, where requirements include good formability, weldability, and corrosion resistance. Balancing performance with cost, ferritic stainless steels are often the preferred choice. Austenitic grades such as SUS409L are widely used, while ferritic grades including SUS429, SUS432L, SUS434, SUS439L, SUS436L, and SUS441 are also common. In practice, SUS409L is primarily used for low- to medium-temperature exhaust parts, while SUS436L, SUS441, SUS429, and SUS434 are suited for higher-temperature applications.

MAG welding of stainless steels with low-oxidizing shielding gases has proven highly effective. With a controlled addition of oxygen or carbon dioxide, Messer’s Inoxline X2 and C2 shielding gases minimize oxidation, maintain arc stability and penetration, and deliver welds that are bright, clean, and visually flawless. For applications that require all-position welding, Inoxline C2 shielding gas is typically used. When robotic welding is combined with positioners to maintain flat-position welding throughout the process, Inoxline X2 shielding gas can be applied to achieve higher welding speeds.

Gases Available from Messer

Inoxline C2:

①Cylinder

②On-site Mixing with Bulk Liquid

Inoxline X2:

①Cylinder

②On-site Mixing with Bulk Liquid

Automotive Seats

Messer’s Ferroline shielding gases support the welding of automotive seats frames – helping to make car seat stronger and safter.

The main components of an electric vehicle seat include the frame, adjustment mechanism, drive motor, control system, power supply, and cushioning elements. Among these, the strength and safety of the seat frame welds are of critical importance. Seat frames are typically assembled by welding steel tubes with stamped steel plates.

Seat frame materials have evolved through three generations. The first generation mainly used low-carbon mild steels, such as Q235 for hot-rolled applications and SPHC for cold-rolled. The second generation introduced alloyed high-strength steels, including high-strength cold-rolled sheets, with tensile strengths ranging from 350 to 650 MPa. These remain the most widely used materials today. The third generation consists of advanced high-strength steels (AHSS), such as QP steels, with tensile strengths in the 590–980 MPa range.

For first- and second-generation steels, rich-argon shielding gas mixtures containing 18–20% CO₂ are commonly applied. Messer’s Ferroline C18 or C20 shielding gases represent this category. For third-generation steels, it is critical that welds achieve both strength and toughness, which requires the use of low-oxidation shielding gases. Messer’s Ferroline C8 or C6 X1 shielding gases are particularly well-suited to meeting these demands.

Gases Available from Messer

Ferroline C20:

①Cylinder

②On-site Mixing with Bulk Liquid

Ferroline C18:

①Cylinder

②On-site Mixing with Bulk Liquid

Ferroline C8:

①Cylinder

②On-site Mixing with Bulk Liquid

Ferroline C6 X1:

Cylinder

You May Also Be Interested in

Bulk Deliveries

Learn More >

Packaged Gas Deliveries

Learn More >

General & Special Equipment

Learn More >

Railway Transit Equipment

Learn More >