Oxy Fuel Combustion in Tank Furnaces

Messer’s Oxy Fuel combustion solution has become a trusted choice for customers seeking to improve efficiency and reduce emissions.

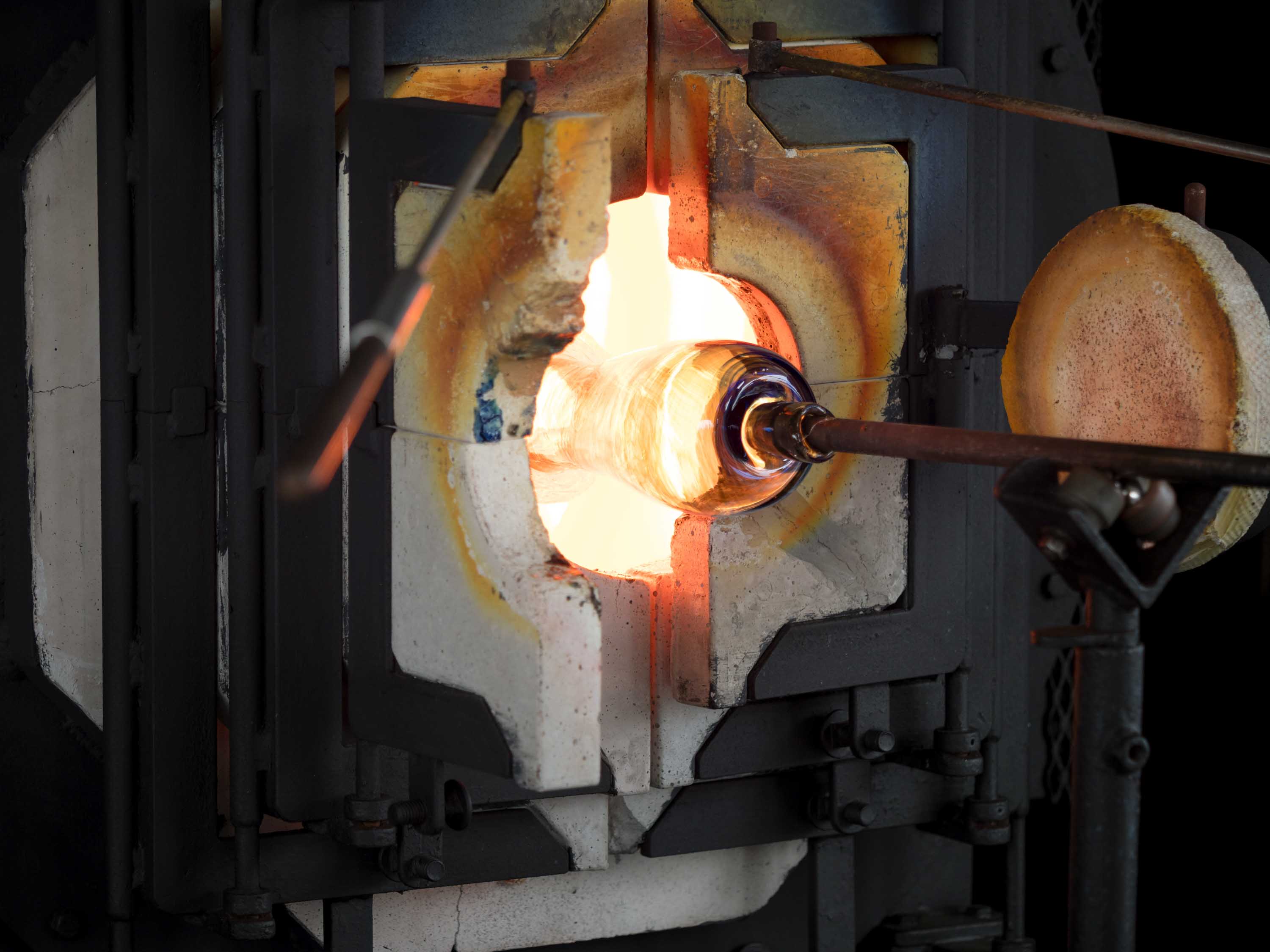

In the glass and ceramics industry, combustion technology plays a decisive role in melting efficiency, energy use, and environmental performance. For Messer, applying Oxyfuel combustion in glass and ceramic tank furnaces is not a new technology, but a proven system that has been successfully implemented worldwide for decades, backed by extensive field experience and continuous optimization under diverse operating conditions. Messer’s Oxyfuel technology has long been a trusted choice for customers seeking greater efficiency and lower emissions.

By replacing air with high-purity oxygen, Oxy Fuel combustion eliminates the heat losses associated with nitrogen. The result is higher flame temperatures and greater heat concentration, which accelerate melting while significantly reducing nitrogen oxide (NOx) emissions. When used in tank furnaces, it speeds up the melting of raw materials and creates a more uniform temperature profile, helping to deliver glass with greater clarity and ceramic glazes with enhanced density and shine.

Messer’s OXIPYR® burner series combines advanced lances with market-leading gases, delivering higher efficiency, more consistent quality and reliable furnace operation for glass and frit.

Why customers choose Messer’s OXIPYR®:

• Efficiency that lasts — Proven fuel savings and reduced operating costs.

• Cleaner production — Substantial NOx reduction, meeting the most demanding environmental standards.

• Superior quality — Enhanced glass clarity and improved density and gloss in ceramic glazes.

• Trusted performance — A mature technology, backed by global references and comprehensive local service.

Gases Available from Messer

You May Also Be Interested in

On-site Oxygen Generation

Learn More >

Bulk Deliveries

Learn More >

Steel

Learn More >