Cathode material

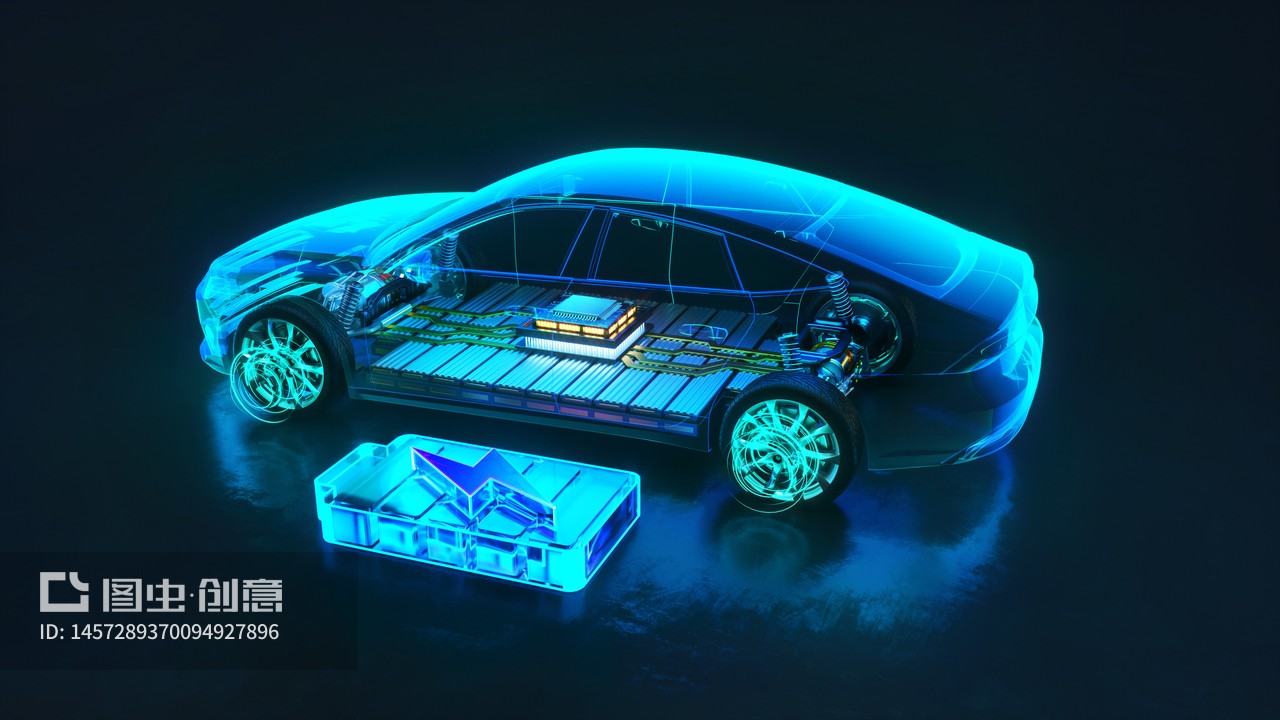

Messer’s high-purity nitrogen delivers strategic apply assurance for leading lithium iron phosphate battery production.

In the production of lithium iron phosphate batteries, oxygen and moisture are primary threats to both material performance and safety. They can cause oxidation, degrade performance, and introduce potential safety risks. Messer’s high-purity nitrogen delivers closed-loop inert protection throughout the entire process, effectively isolating oxygen and moisture, and providing a critical safeguard for ensuring battery quality.

• Ultimate Protection – Encompasses key processes such as sintering, crushing, drying, and packaging, maintaining a stable, oxygen-free, ultra-low-moisture environment. This prevents material oxidation and enhances crystal purity and consistency.

• Performance Enhancement – Ensures the structural stability of cathode materials, significantly extending battery life and improving safety.

• High Efficiency & Energy Savings – Features an optimized nitrogen recycling design to minimize energy consumption and reduce operating costs.

• Flexible & Reliable – A modular system that easily adapts to production lines of varying scales, ensuring stable operation and offering simple, low-maintenance upkeep.

Gases Available from Messer

On-site Generation:

Bulk:

Liquid N₂

You May Also Be Interested in

On-site Nitrogen Generation

Learn More >